Are Expensive Thermal Pastes Worth It?

Thermal paste is key for ensuring the proper temperature range for the key components in your PC, mainly the CPU and GPU. It acts as a medium for improving the transfer of heat from the processor or graphics card to the cooler so that the heat can be dissipated efficiently.

Otherwise, without the thermal paste, the PC would be prone to overheating, causing thermal throttling and performance degradation with a risk of damage in selected cases.

For both budding and experienced PC builders, understanding how vital selecting quality thermal paste is. Using premium thermal paste works towards keeping your system cool, allowing it to run stable and be reliable for years, whether this is gaming or working on demanding applications.

What Is Thermal Paste?

Thermal paste, also known as thermal grease, is bridging material between a CPU or GPU and the cooler unit that allows for efficient heat transfer. Thermal paste is primarily used to increase thermal conductivity, for without this paste, the heat cannot dissipate fast enough and the chip will start overheating.

It consists of a base binder (usually silicone), something that conducts thermal energy, that is either metal, ceramic, or carbon, and fillers that provide consistency and usability. Applying the appropriate thermal grease is important for both CPUs and GPUs to maintain their cooling efficiency and to keep the components within safe temperature limits.

Why Do You Need Thermal Paste?

Heat transfer is fundamental physics, and thermal paste works on this principle. High amounts of heat are generated by CPUs and GPUs, and if thermal transfer is not effective, these components can instead overheat and be unstable, crash, or suffer permanent damage.

It is highly recommended to use a thermal paste for the efficient conduction of heat through your system. It increases the thermal conductivity between CPU, GPU, or other heat-sensitive components from their respective cooler to avoid overheating and optimum functioning. Here’s why it matters:

Filling of Microscopic Gaps

The thermal paste fills the micro-gaps, ensuring maximum surface contact to absorb heat. The better the paste, the better it fills these gaps, which means better heat transfer.

Thermal Conductivity Improvement

Thermal paste fills tiny air gaps in between processor (CPU or GPU) and cooler for better heat transfers. Now heat generated from the component transfers to cooler more efficiently.

Prevention from Overheating

Overheating is one of the usual causes of reduced performance and hardware failure. When thermal paste is applied, you know that your CPU and GPU are going to be kept within the safe temperature ranges, eliminating the danger of damaging thermal build-up or thermal throttling.

Maximizing Contact

Paste ensures proper contact of processor with cooler, which is crucial for effective heat dissipation. Without a uniform covering of thermal paste, wee small air pockets would form reducing your cooling system performance.

How Thermal Paste Works?

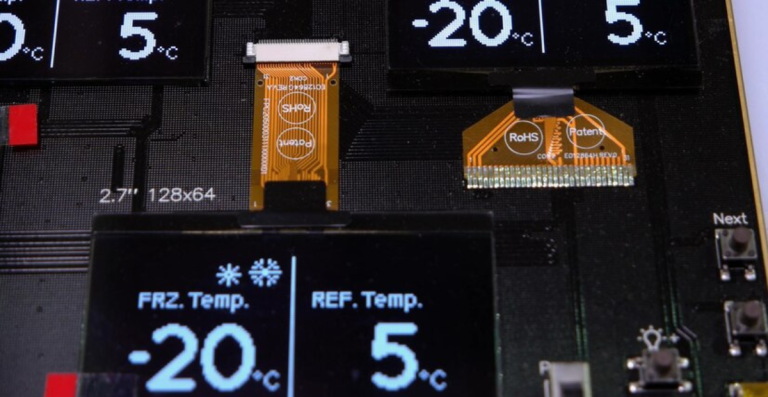

Also, the paste does not only become crucial for the CPU; the GPU of the PC, as well as any other parts that generate heat, also needs thermal paste. in fact, our real world discussions may grow more meaningful to these temperatures:

- Effects on PC Build and Overclocking: Indeed, the reason for building a PC is to be able to operate at tolerable temperatures (especially while overclocking) when you use the machine for gaming or productivity. With thermal pastes, both CPUs and GPUs remain within their optimal operating temperature levels. More heat is generated from the overclocking processes, and the best thermal paste will help such heat dissipation.

- Temperature Reductions and Hot Spots: You will be able to lower the temperatures of your CPU and GPU much more by using thermal paste correctly. This temperature drop helps to eliminate the hot spots caused by excessive heat that could throttle performance or even cause the components to fail.

- Compatibility With Modern Heatsinks: Today, heatsinks and coolers are engineered to work with thermal pastes to enhance heat dissipation. Whether you make use of air cooling or liquid cooling, you can rest assured that the different types of thermal paste you’ve applied are interfacing with the cooler and the component aptly, leading to much improved overall performance.

Types of Thermal Compounds

Thermal compounds come in various forms, and each one is utilized for various purposes depending on how well it works, how safe it is, and how simple it is to use. Whether you are building budget rig or an elite gaming rig, the thermal compound you cgiise can affect heat management and life of the system.

Silicone Thermal Glue

Thermal paste silicone is often found ready installed in stock coolers or included in budget setups. They do application with ease and work anywhere for general use but are not the sharpest in terms of thermal performance. For most everyday users or office setups, they will, however, do the job.

Metal-Based Paste

These pastes, usually made of materials like aluminum or silver, stand out for their high thermal conductivity. Metal-based pastes are meant for high-performance systems that will often deal with overclocking. However, be very careful with their applications since these compounds are electrically conductive, thus the possible short circuits.

Ceramic Paste

Ceramic thermal compounds are well between metal and non metal because they are much safer than metal ones but still give good performance. Also, ceramic thermal compounds are usually chosen by many users because they are safe and long term stable.

Carbon Paste

These types of compounds are carbon-based. Because of their excellent heat transfer, long life, and non-conductive nature, they are preferred over other alternatives. These are widely-used thermal pastes in both gaming PCs and productivity computers because they represent the perfect compromise between performance and safety.

Thermal Pads vs. Thermal Paste

Thermal pads are more user-friendly and easier to clean, making them very good for do-it-in-a-hurry installs. However, these pads generally perform poorer than a good thermal paste. For gamers, streamers, and creators, paste remains the favorite choice for hard-core heat control.

Thermal Interface Material Composition

Knowing the details going into a thermal interface material (TIM) helps you make an informed decision when it comes to systems that will require intense cooling. The most effective formulation will influence system safety, performance, longevity of the paste, as well as other factors.

What is a Thermal Interface Material (TIM)?

TIM is any material that is used for the purpose of filling in the gap between the heat generating circuit components (CPUs, GPUs) and coolers in order to minimize the thermal resistance of the whole system. It extracts heat from the leading edge vessels, where it broadens the overall flow cross-section housing the heat.

Key materials used in Thermal pastes

The primary components in thermal pastes are:

- Binders: These dictate uniformity and also affects spreadability

- Filler: These impacts the conductivity and the performance of the compound

Common fillers are:

- Metal particles (e.g. silver, aluminum)

- Carbon compounds

- Ceramic based materials

How various TIMs impact the thermal conductivity

The efficiency with which heat is supplied to the apparatus is directly related to the type of filler and the performance of any particular compound does have influence on heat.

- Based on metal: Efficiency is very high, but electrically dangerous

- Based on ceramic: Conductivity is lower but more forgiving

- Based on carbon: High performance and risk free from electrical hazards.

Viscosity plays an important role too thick paste might remain in position longer compared to thinner ones that spread more readily.

Performance Differences: Expensive vs. Budget Options

Not all thermal pastes are created equal. Some come with premium ingredients that promise better cooling, while others are basic and affordable. Understanding the real performance differences between expensive and budget options can help you make a smart buying decision.

Premium Thermal Paste Ingredients

The quality of the components significantly determines the performance efficacy of a thermal paste.

- The higher-end pastes are such that they utilize ultra-fine metal particles or carbon-based compounds.

- The lower-cost pastes are usually filled with a generic silicone or low-grade ceramic filler.

- Premium-grade materials usually give a more consistent heat transfer especially under load.

Thermal Conductivity and Viscosity

Both factors affect the even spread of the paste and its heat transfer.

- Higher viscosity pastes are thicker and adhere longer compared with other pastes.

- Lower viscosity, on the other hand, should be quite good for ease of application but can be too thin in coverage.

- The thermal conductivities in the premium pastes are significantly above those seen in the budget types.

Cooling Performance Metrics

Thermal performance is probably measured best by the temperature jugged in situ.

- The costs for such pastes can reduce at temperatures 2-5°C lower than budget products.

- These can be very critical for overclocking systems and high-performance builds.

Liquid Metal vs. Traditional Pastes

Liquid metal compounds are the ones known for being able to conduct heat with the best efficiency in all. But there are also part-threats in using this method.

- Ideal for setups that require extreme performance

- Attacks aluminum instead of these heatsinks. The kind utilizes the plastic bag as a catch-all because it still leaves residue behind after installation.

- Conventional pastes are safer and easier to use by all end-users.

Real-World Impact on CPU and GPU Temperatures

On paper, numbers are one thing, but their practical application provides a more lucid picture. When it comes to determining how hot your components get and how well your system can withstand prolonged loads, whether on a CPU or GPU, thermal paste is crucial.

Effects on PC Build and Overclocking

Overall build stability may be impacted by the thermal paste selection.

- Systems using premium thermal paste demonstrated more stable temperatures under stress in performance tests.

- High-quality thermal paste facilitates improved heat transfer during overclocking.

Temperature Reductions and Hot Spots

Uneven paste application or poor-quality compounds can cause hot spots.

- Good thermal paste ensures even temperature distribution

- Helps prevent overheating in isolated regions of the chip

Compatibility with Modern Heatsinks

Thermal paste needs to pair well with modern cooling systems for optimal performance.

- Premium pastes generally perform well with both air coolers and AIO liquid coolers

- Always check for electrical conductivity risks when using metal-based compounds with aluminum coolers

Considerations for Choosing Thermal Paste

Choosing the right thermal paste isn’t just about picking the most expensive option. It’s about understanding your setup, your cooling needs, and how each factor from application to materials can influence performance.

Installation and Application Techniques

One of the most important aspects of using thermal paste is applying it correctly. Even the best paste can underperform if it’s spread the wrong way or in the wrong amount.

- Apply a small, pea-sized dot in the center of the CPU

- Avoid spreading it manually and let the cooler do the work

- Never apply too much; it can spill over and reduce efficiency

Mounting Pressure and Thermal Connection

How tightly your cooler is mounted also affects how well the paste works. Proper mounting ensures even pressure, which helps the paste form a consistent layer between the CPU and heatsink. This improves thermal transfer and reduces the chance of hot spots forming.

Electrical Conductivity and Safety

Some high-performance pastes are electrically conductive, especially those with metal content. While they offer great thermal performance, they also bring risks. Make sure you don’t let the paste touch exposed circuitry, and always check the specs before applying.

Longevity and Manufacturing Quality

Not all thermal pastes age the same.

- Higher-quality pastes tend to last longer without drying or cracking

- Signs like increased temperatures or flaky residue may mean it’s time to replace it

Is it Worth Upgrading from Stock Thermal Paste?

If you’re wondering whether it’s worth replacing the paste that came pre-applied to your CPU cooler, the answer often depends on your usage. Stock thermal compounds are usually just enough to get the job done, but they’re not designed for optimal performance.

Aftermarket thermal pastes offer better materials, improved thermal conductivity, and longer durability. For gaming, content creation, or overclocking, upgrading your thermal paste can result in noticeably cooler temperatures and more stable performance.

However, if you’re using your PC for everyday browsing or light workloads, the benefits might be minimal. But if you ever plan to push your system harder, replacing the stock paste is a smart and inexpensive upgrade.

FAQ